The following post was written by Rice Lake Weighing Systems, our featured manufacturer this month. Rice Lake’s extensive line of weighing solutions, process control equipment and measurement systems can be found almost anywhere. Whatever the need, and wherever the installation—Rice Lake products can provide the solution.

Choosing the Best Crane Scale for Your Application

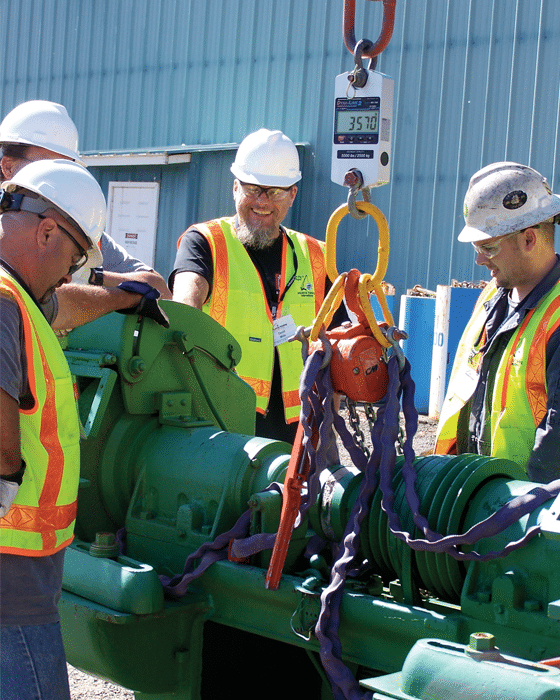

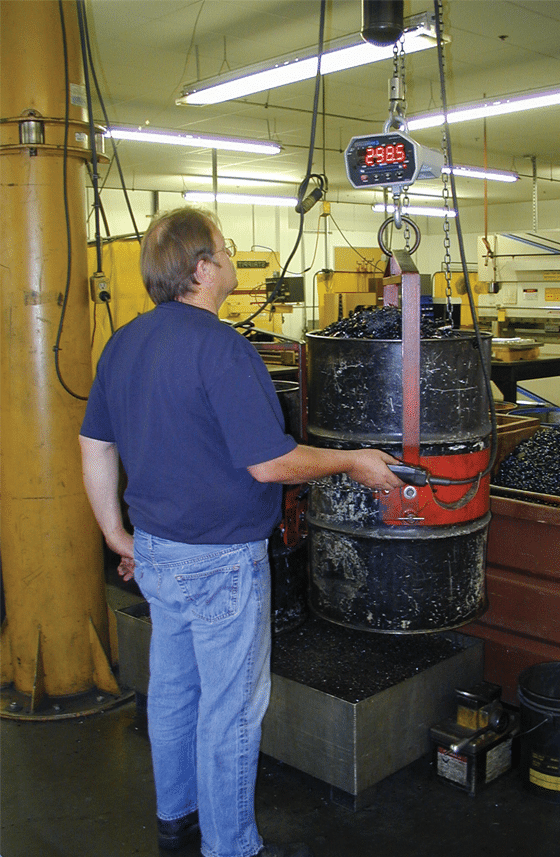

Crane scales are fundamental in countless applications, ensuring safety and delivering accurate load measurements. When used properly, crane scales can help prevent unsafe conditions by measuring the operational load in real-time and providing immediate feedback to operators and safety systems. Exploring your goals for overhead weighing and analyzing aspects of your environment will help you determine the crane scale best suited for your application.

Consider Your Overhead Weighing Goals

Load monitoring maintains employee safety by preventing crane accidents, regulates compliance and protects equipment. To ensure compliance, the scale should meet or exceed OSHA, ANSI, ASME and other local safety standards. Accuracy is generally 1-3% full scale.

Process control delivers accurate weighments, real-time information and integration with manufacturing data acquisition systems, often required by in-process crane scales. Accuracy is 0.1% full scale.

Data integration systems are used to increase informational exactness and control, stream data from the weighing system to customer database program, go paperless and eliminate or reduce human error.

Determine What Crane Scale or Weighing Solution You Need

Common below-the-hook overhead weighing equipment includes an integrated scale, an integrated sensor, and RF and signal processors. From bridge cranes to gantry and tower cranes, rugged, reliable overhead weighing solutions are available for many different applications. Below are common types of cranes and the ideal weighing system for each. Rice Lake Weighing Systems’ MSI brand offers comprehensive overhead weighing products designed to increase safety and efficiency in any environment.

-

Monorail Hoist

The most common hoist, a monorail hoist, uses a chain hoist or block with wire rope or cable and has a one- to 10-ton capacity. Due to their versatility and high capacity, monorail hoists are most commonly found in industrial facilities.

-

Jib Crane

A jib crane features a horizontal member supporting a moveable hoist, commonly seen in workstation applications and machine shops. It is also useful in production and shipping where there is often a need to weigh smaller machine parts.

-

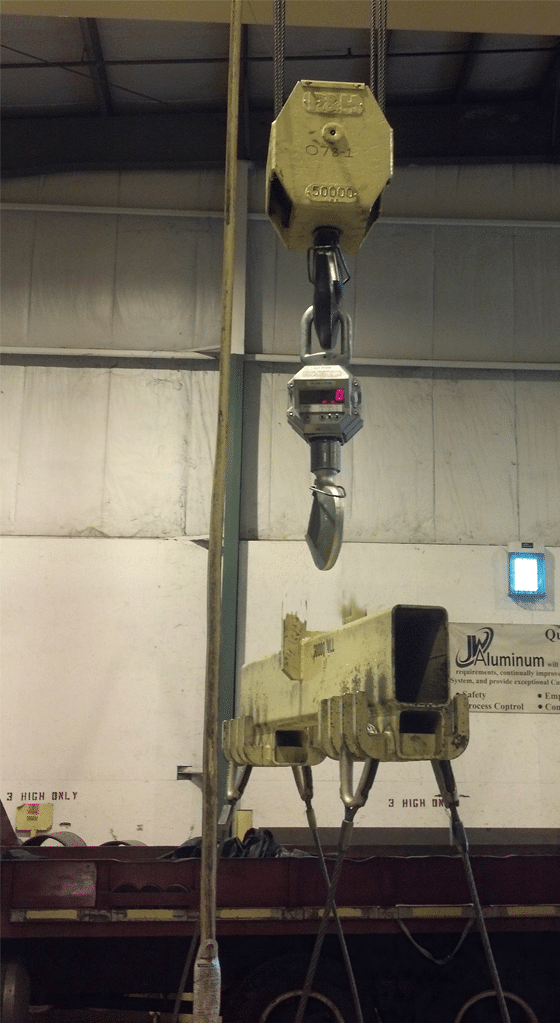

Bridge Crane

In a one- to 100-ton bridge crane, the trolley moves laterally while the bridge moves longitudinally. In turn, this offers a wide range of motion, easily integrates into existing applications and increases safety and efficiency.

-

Rail Mounted or Rubber Tire Gantry

Frequently found in factory applications such as steel yards, paper mills and other heavy industrial facilities, the rail mounted or rubber tire gantry has similar movement to a bridge crane. They are common on rails or tires in heavy capacity weighing industries, where capacities can range from one to 200 tons.

-

Semi Gantry

A semi gantry is essentially a gantry crane with one end of the bridge rigidly supported on one or more legs that run on a fixed rail or runway. The other end of the bridge is supported by a truck running on an elevated rail or runway.

-

Integrated Weighing Solutions

Most bridge, monorail, jib, gantry and straddle crane safety systems employ an integrated load sensing system. An integrated load sensor is designed to be permanently installed and integrated where load is consistently applied relative to the actual load the crane is handling, generally with sheave pin, load link and compression designs.

-

RF and Signal Processing Solutions

Add traceability and transparency to your processes. With several methods of radio frequency (RF) technology, wireless communication products are an easy integration for nearly every industry or environment.

Rice Lake Weighing Systems’ MSI

Whether used in shipping, material handling, foundries, shipyards, construction or freight applications, Rice Lake’s trusted MSI overhead weighing solutions assist in creating safe and efficient operations. Learn how a crane scale system can benefit your operation at www.ricelake.com/msi.

Let us help you choose the best crane scale

Michelli Weighing & Measurement is your authorized Rice Lake supplier. Call our experts today & tell us more about your application. We can help you identify the right equipment for your operations and your budget.

Contact your nearest Michelli location today.