Precise Measurement Readings: Understanding the Science Behind Calibration

By definition, precise measurement readings are repeatable, meaning a precise measurement device can produce the same reading over and over. During calibration, a technician uses a measurement standard with a known value, such as a test weight, to test the measurement reading produced by a device, then adjusts the device as needed to ensure the reading produced matches the known value of the standard, within a given tolerance. For example, to test a scale, a technician places a certified test weight (with a known value) onto a scale platform to determine whether the measurement reading produced is equal to the known value of the test weight. If the reading produced does not equal the known value of the test weight, the tech will adjust the device until the reading matches.

Accuracy refers to the measurement reading’s proximity to the known value. So if the test weight weighs 5 lbs, and the scale produces a reading of 5 lbs, the scale is producing accurate readings. However, if the scale produces a reading of 1 lb, that reading is inaccurate.

Precision is the ability of the device to repeat that measurement reading consistently. Therefore, if that 5 lb test weight is placed on the scale platform 10 times, and the scale produces a reading of 5 lbs each of those 10 times, then the device is producing precise readings, as well as accurate readings. (Learn more about the difference between these two terms in this blog post: Accuracy Versus Precision | The Difference Between Accuracy & Precision)

When it comes to weighing and measurement, precision isn’t just nice to have—it’s essential. Whether you’re weighing ingredients for food production, ensuring compliance in manufacturing, or measuring precious metals, readings that are both accurate and precise matter.

Let’s review the science of scale calibration to learn more about precise measurements.

Precise Measurement Readings Must Be Produced During Calibration

Calibration is the process of comparing the measurement reading produced by a devices against a known measurement standard in an effort to ensure the device’s accuracy. In the case of scales, the measurement standard comes in the form of certified test weights that adhere to strict national or international standards, such as those set by the National Institute of Standards and Technology (NIST). In the case of dimensional precision measurement devices, gage blocks would be used as the measurement standard.

Let’s discuss a scale calibration, during which a test weight with a known value of 10 lbs is used. If this test weight is utilized in the calibration of a bench scale, when it is placed on the scale deck, the indicator should produce a reading of 10 lbs. If it does not, the scale must be adjusted, or calibrated, so that the reading produced is accurate, within the given tolerance for that particular type of equipment. During calibration, we identify any deviations from true weight and adjust the device, in this case a scale, to eliminate those errors.

Once the device is calibrated, the test must be repeated several times to demonstrate the consistency of the measurement device. This exercise proves the precision of the device and helps the technician ensure that there are no underlying issues causing a deviation, or incorrect measurement reading.

The Science Behind Accurate & Precise Measurement Readings

Accurate and Precise measurement readings rely on three critical factors:

- Consistency

For a scale to be reliable, it must provide the same reading every time the same weight is placed on it. To refer to a device as “precise” is to say that the measurement readings produced by the device are repeatable and consistent across multiple uses. - Traceability

Calibration uses certified weights that are traceable to a known standard and have been certified to be accurate by an accredited body such as NIST. This traceability ensures that your measurements are accurate when compared with other known standards worldwide. - Environmental Considerations

The science of calibration also accounts for environmental factors that can affect accuracy & precision. Variations in temperature, humidity, or even air pressure can influence scale performance. Each device has an allowed tolerance range, or a range within which acceptable readings can fall.

For example, if a truck scale has an allowed tolerance range of 5 lbs, it is considered accurate as long as the readings it produces are within 5 lbs of the known value of the test weight used in its calibration. So if a 50 lb test weight is used during calibration, and the truck scale produces a reading of 52 lbs, the scale is considered accurate because the measurement reading produced falls within the 5 lb tolerance range.

Skilled calibration technicians consider these variables and calibrate the device so that it produces accurate and precise measurement readings within the given tolerance range to deliver optimal results during operation.

Regular Calibration Helps Prevent A Decline in Precision Measurement Readings

A decline in precision measurement readings, or a gradual loss of repeatability, can happen naturally over time with normal wear and tear. Even slight discrepancies can have significant consequences, such as:

- Lost Revenue: Inaccurate measurements can lead to undercharging or overcharging customers, leading to revenue loss or a bad reputation. (Use our inaccuracy cost calculator tool to determine how much revenue you could be losing due to inaccuracy.)

- Regulatory Issues: Many industries have strict guidelines for weighing accuracy, and non-compliance can result in legal repercussions, including fines or penalties.

- Operational Inefficiencies: Faulty measurements can lead to production delays, material waste, or rework.

Regular calibration minimizes these risks by ensuring that your equipment remains accurate and precise.

Michelli: Your Precision Partner

At Michelli Weighing & Measurement, we specialize in precision and accuracy. Here’s how we help you achieve precise measurement readings:

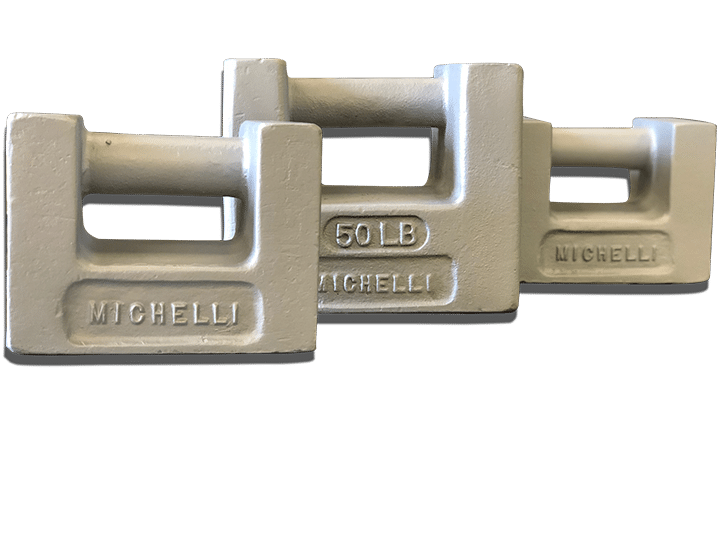

- State-of-the-Art Equipment: Our certified calibration weights and advanced tools ensure the highest level of accuracy & precision.

- Expert Technicians: Our highly trained team understands the nuances of calibration and performs thorough checks to meet or exceed industry standards.

- Documentation & Compliance: We provide detailed calibration certificates, making it easy to identify devices with repeated errors that may be nearing their useful life, and maintain compliance with regulatory requirements.

- Preventative Maintenance: We offer maintenance plans to keep your equipment operating in peak condition year-round. With our maintenance plans, you determine how often you would like our experts to test your scale, make adjustments if needed, and ensure that all components are working properly. Maintenance plans help you address problems in advance to reduce unplanned downtime, and ensure you get the best rate on your service and any required replacement parts.

Need Precise Measurement Readings? Then You Need Michelli.

Accurate & precise measurement readings are the foundation of operating at peak efficiency. Calibration is the key to ensuring that your equipment is producing dependable readings. With over 75 years of experience and a commitment to excellence, Michelli is your trusted precision partner, here to ensure your equipment performs at its best, so you can focus on operations.

Ready to fine-tune your precision equipment?

Contact Michelli today and experience superior service firsthand.