When it comes to needing surface roughness measurements you can trust, the Mitutoyo SJ-220 Surftest is a standout choice for capturing high-precision data on the go. From the production floor to remote field sites, this compact device supplies fast, accurate surface roughness measurements wherever they’re needed, reducing downtime and preventing costly errors.

Powered by a reliable on-board and featuring an intuitive touchscreen design, the SJ-220 adapts to multiple environments and measurement standards while offering flexible data management through USB, RS-232C, or wireless U-WAVE communication. Whether you’re performing quick spot checks on the shop floor or detailed final inspections in the lab, the new Mitutoyo SJ-220 offers a powerful combination portability, accuracy, and on-board data processing to help you maintain consistent surface roughness quality control almost anywhere.

Below, we’ll explore how this versatile portable surface roughness tester simplifies workflows, ensures measurement consistency, and supports a wide range of application needs. We’ll also look at how its advanced features—like multi-language support, Bluetooth® connectivity, and intuitive software tools—enable teams to collaborate efficiently and keep pace with demanding production schedules.

Why Portability Matters for Surface Roughness Testing

-

Reduces Production Downtime

In many production environments, workpieces can be large, heavy, or fragile. Having to move them to a dedicated inspection station is not always feasible. With the Mitutoyo SJ-220 in hand, inspectors can measure surface roughness at the source, saving time and avoiding any potential damage in transit. The device’s lightweight design (display unit weighing about 330 g, drive unit around 180 g) and built-in battery, capable of an estimated 1,000 measurements on a full charge, make it possible to execute quick, repeated tests without tethering yourself to an AC outlet. - On-the-Spot Quality Checks

In many modern shops, an operator may need to check a component mid-production to ensure it meets tolerance requirements before proceeding to the next step. With the versatile portable surface roughness tester in hand, you can run a measurement right at the CNC machine or forging station. This helps prevent manufacturing errors from propagating through subsequent operations, thus saving time, materials, and rework costs.

-

Adapting to Varied Environments

Outside the usual manufacturing floor, you might need to conduct surface inspections in the field or in areas with no stable power source. The SJ-220’s internal NiMH battery and modest energy requirements make it well-suited for places like construction sites, shipyards, oil fields, repair stations, etc., where consistent power and stable Wi-Fi signals are not guaranteed. If you travel from one workstation to another or between buildings, you can tuck the SJ-220 into its included handy case and continue measuring without missing a beat.

Featured Highlights of the Mitutoyo SJ-220 Surftest

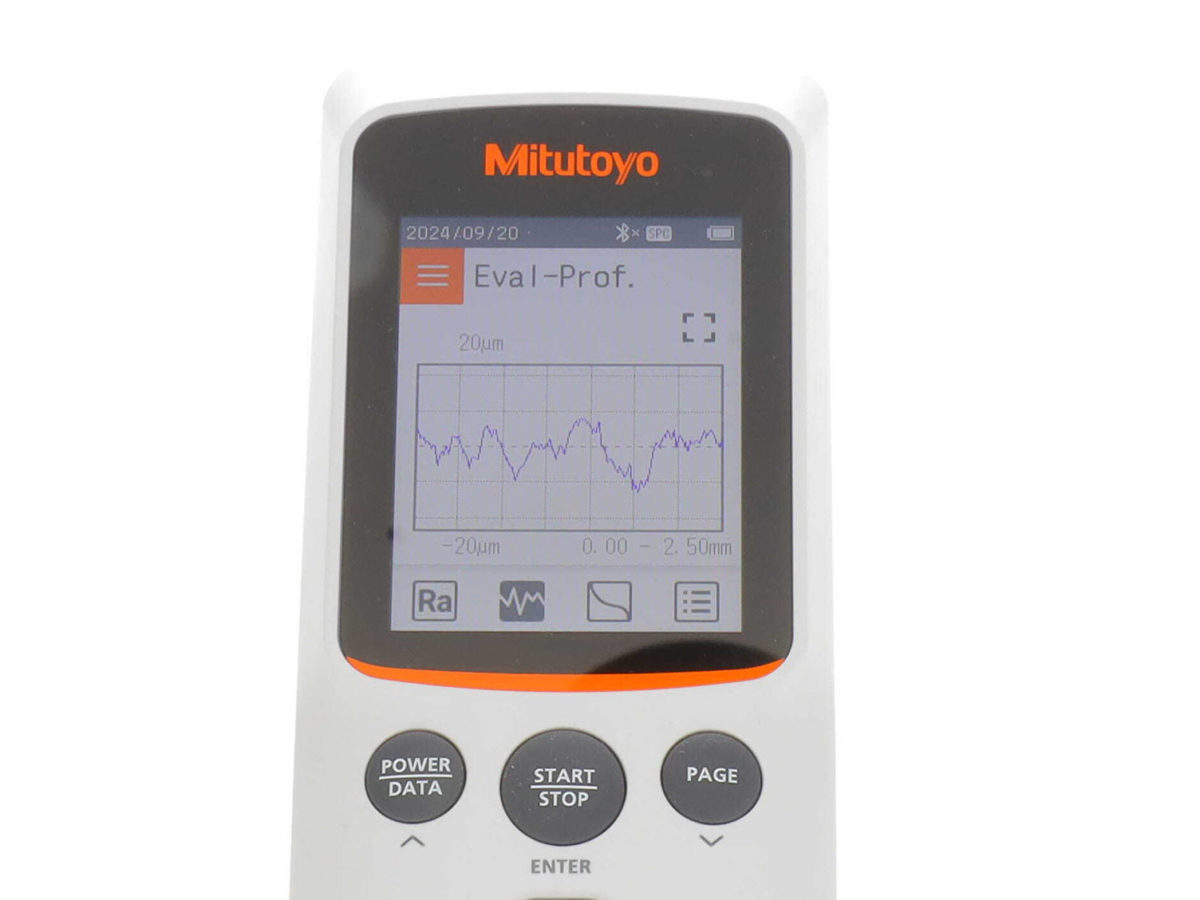

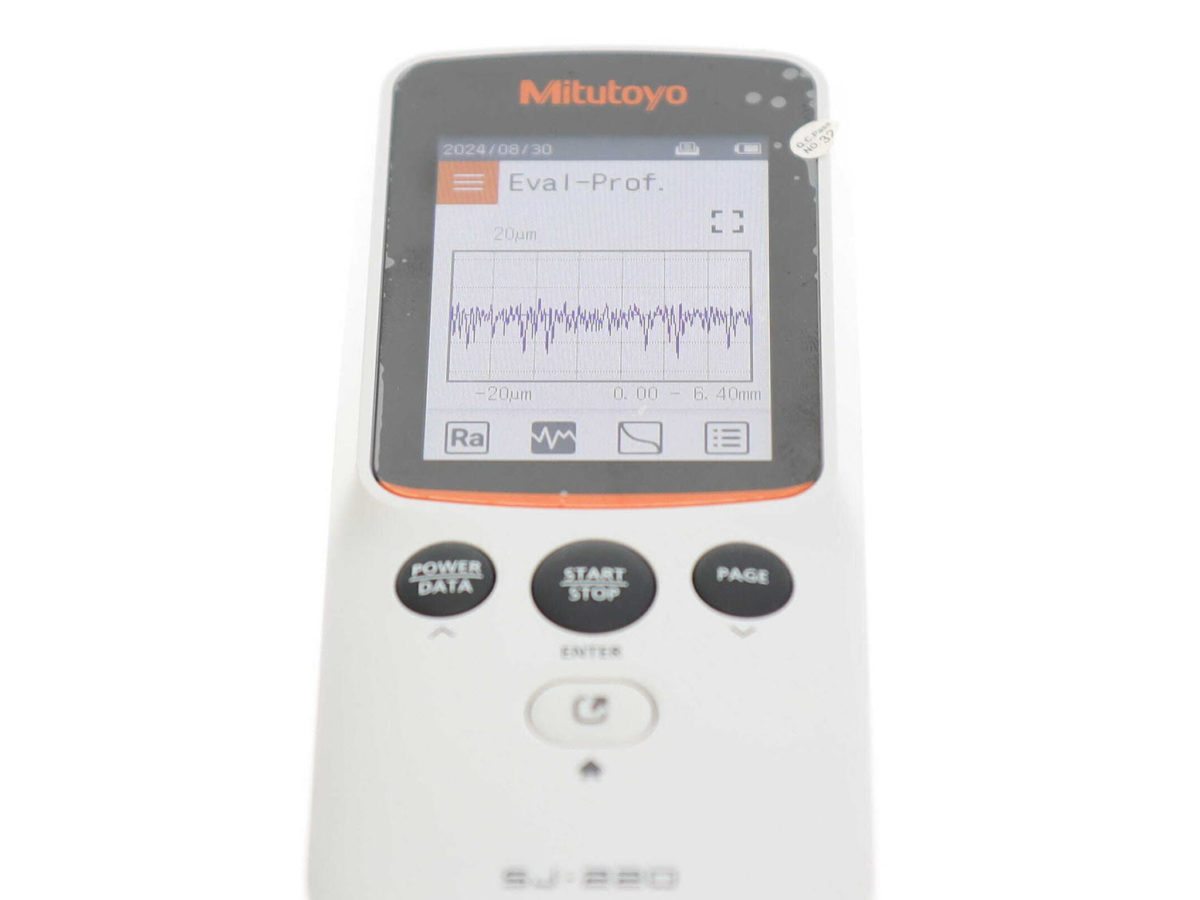

Intuitive Touchscreen Operation

One of the immediate standouts of this portable Surftest is its 2.8-inch color touchscreen interface. It offers pinch, swipe, and flick capabilities, letting you navigate menus and measurement data quickly, even with minimal training. If you wear gloves, no worries. The SJ-220 also includes buttons for essential operations, ensuring that you can work with it in various shop-floor conditions. A convenient “PAGE” key lets you disable the touchscreen if you want to avoid accidental presses.

Measurement Accuracy and Standards

Despite its portable design, the SJ-220 does not compromise on accuracy. It covers a measuring range of up to 360 μm, with resolutions down to 0.2 nanometers (depending on the chosen range). Mitutoyo calibrates and certifies the SJ-220 to meet multiple global standards:

- JIS B 0601 (1982, 1994, 2013)

- ISO 4287 (1997)

- ASME B46.1

- ISO 21920 (the latest surface texture standard)

- VDA2006

This broad compliance ensures that your measurements remain comparable and valid in international contexts.

Three Drive Unit Options

Mitutoyo offers three drive unit configurations:

- Standard Drive Unit

- Bestselling, straightforward solution with a 16 mm measurement length.

- Pairs seamlessly with standard or custom detectors (styli) for a variety of measurement tasks.

- Retractable Drive Unit

- Ideal for automated environments or setups where the stylus must avoid accidental contact.

- Can retract by 1 mm to help you maneuver around jigs, clamps, or fixtures.

- Transverse Tracing Drive Unit

- Moves the stylus sideways rather than lengthwise, great for measuring crankshafts or narrow spaces.

- Perfect when a standard or retractable approach won’t physically fit.

With these variations, the SJ-220 can adapt to a huge array of workpieces, from small turned parts to large, oddly contoured castings.

Flexible Data Management

Modern manufacturing relies on robust data traceability, so the SJ-220 integrates multiple methods for exporting results. These include:

- USB Communication: Connect to a PC to transfer measurement data directly for reporting, or to set measurement parameters remotely using the “SJ-Communication-Tool.”

- Wireless U-WAVE-TIB: An optional Bluetooth® module that lets you communicate wirelessly with PCs, tablets, or phones. You can even push measurement conditions from a PC to the tester or trigger measurements remotely which is perfect for areas where cables get in the way.

- Digimatic & RS-232C Ports: Use Mitutoyo’s Digimatic Mini Processor (DP-1VA LOGGER) or standard RS-232C cable to output data instantly. This is particularly helpful if you need a printed copy on the spot for documentation or sign-offs.

Battery and Charging

A single full charge typically lets you perform around 1,000 measurements. And because it charges via USB Type-C, you can power it from a standard USB port, a USB hub, or the supplied AC adapter. This universal compatibility cuts down on the clutter of dedicated chargers.

Built-In Memory and Easy Storage

On the device, you can store up to 10 sets of measurement conditions and one measurement result. You can also use an optional microSD card (sold separately) to expand storage, saving up to 500 sets of measurement conditions and 10,000 measurement results—a significant advantage for long-term data collection or multi-shift operations.

Multi-Language Support

The SJ-220 supports an impressive 25 languages, including English, Spanish, German, French, Japanese, Korean, Thai, and more. In international or multilingual production settings, this helps standardize measurement procedures across teams, streamlining training and daily use. Operators can easily switch from one language to another, letting a diverse workforce adapt quickly.

How the SJ-220 Enhances Your Workflow

Quick Start, Quick Results

- Fast Setup: Attach the drive unit with the appropriate detector, press the power key, and you’re ready to measure.

- Multiple Profiles & Parameters: The instrument automatically calculates parameters such as Ra, Rz, Ry, and more. If you’re verifying compliance to a specific standard (e.g., ASME B46.1), you can load that preset condition.

- One-Touch Measurement: The START/STOP button initiates the measuring cycle. Within seconds, the surface roughness data appears on the screen, letting you decide GO/NG right away.

At Michelli Weighing & Measurement, we’re proud to partner with manufacturers like Sartorius to bring these innovative solutions to our customers. If you have questions about maintaining accuracy, optimizing calibration schedules, or exploring sustainable equipment options, our team is here to help.

Minimizing Human Error

With the versatile portable surface roughness tester placed right where you need it, you can significantly reduce the chances of errors introduced by repositioning or mishandling parts. The SJ-220’s direct data transfer capabilities, including Digimatic cables, the optional U-WAVE wireless modules, or USB, also eliminate the typical transcription mistakes from manual data entry.

Enhanced Collaboration

Quality teams, operators, and supervisors often benefit from real-time data sharing. Thanks to the optional U-WAVE-TIB transmitter unit and Mitutoyo’s dedicated “SJ-App” or “SJ-Communication-Tool” software, results can be instantly pulled into a smartphone, tablet, or PC. This means your entire production team can stay in sync. Engineers who are off-site can also interpret results quickly if the data is shared through a collaborative platform.

Minimizing Human Error

Beyond daily checks, you might want deeper analysis for R&D or process improvement. The SJ-220 integrates neatly with:

- MeasurLink®: Mitutoyo’s data management software for real-time statistical process control.

- FORMTRACEPAK-AP: A powerful analysis tool for advanced graphing and parameter evaluation.

By combining the SJ-220’s speed with robust software, you get a complete system for tracking historical data, performing deeper SPC calculations, and producing well-organized inspection documents.

Practical Tips for Maximizing the SJ-220

Calibrate Regularly

Surface roughness tests are highly sensitive. Use the recommended Mitutoyo roughness specimen (e.g., 178-601-1 for metric) and follow the built-in calibration instructions. The device offers Ra or multi-point averaging calibrations, so you can ensure consistent, accurate measurements day-to-day.

Choose the Right Drive Unit & Detector

- Standard Drive Unit: Great for most general-purpose tasks.

- Retractable: Ideal if you’re frequently measuring parts with fixtures or jigs.

- Transverse: Required for specialized surfaces such as axial measurements on cylindrical parts.

Detectors (styli) come in different tip radii and angles—2 µm radius for fine surfaces or 5 µm if you’re testing rougher surfaces. Confirm that the stylus angle suits your standard: 60° for finer measurement or 90° for typical.

Accessorize Thoughtfully

Optional accessories like the height gage adapter (for stable vertical checks) or the foot switch (hands-free data logging) can significantly speed up measurement routines. You can also attach a nosepiece for cylindrical surfaces or a point-contact adapter to handle small grooves, ensuring you’re capturing the correct portion of the surface.

Real-World Applications

- Automotive Assembly Lines: Inspect camshafts, crankshafts, or engine blocks directly on the line to confirm they meet roughness requirements before the next assembly station.

- Machine Shops: Spot-check turned or milled parts for conformance to tight Ra specs without having to walk all the way to a separate QA lab.

- Field Services: Oil and gas, power generation, or aerospace repair teams can quickly evaluate wear patterns on turbines, pipelines, and more, right where the equipment is located.

- Incoming Part Inspection: Receive castings or forgings from a supplier? Use the SJ-220 to confirm the incoming goods match contractual roughness specifications.

Balancing portability with high-precision measurement often feels like a challenge, but the Mitutoyo SJ-220 Surftest proves it’s more than possible. Designed to be the versatile portable surface roughness tester that manufacturing floors demand, it streamlines quality checks by allowing you to measure roughness on-site, no matter the environment. Its intuitive touchscreen interface, multi-language support, robust data capabilities, and battery-powered convenience empower operators to gather precise surface data in seconds.

Whether you’re handling quick in-line checks, final inspection in a temperature-controlled lab, or field services out in remote locations, the SJ-220 stands as a go-to partner for reliable and accurate surface roughness measurements. It ensures you not only measure your components right where they are but also maintain the stringent quality standards your customers require.

The previous post was provided by Mitutoyo. Visit the Mitutoyo website here. Mitutoyo’s ultra-precise measurement solutions bring improved performance to countless industries, including aerospace, medical, automotive and energy. With more than 5,500 products—the largest product portfolio of any commercial metrology provider—Mitutoyo has the solutions you need to meet today’s metrological challenges and customer expectations.

Interested in a Mitutoyo SJ-220 Surftest Surface Roughness Tester?

Talk to our experts about how a Mitutoyo SJ-220 Surftest Surface Roughness Tester can help you increase accuracy while simplifying workflow.