Manufacturing

The manufacturing measurement equipment you need with the service you can trust

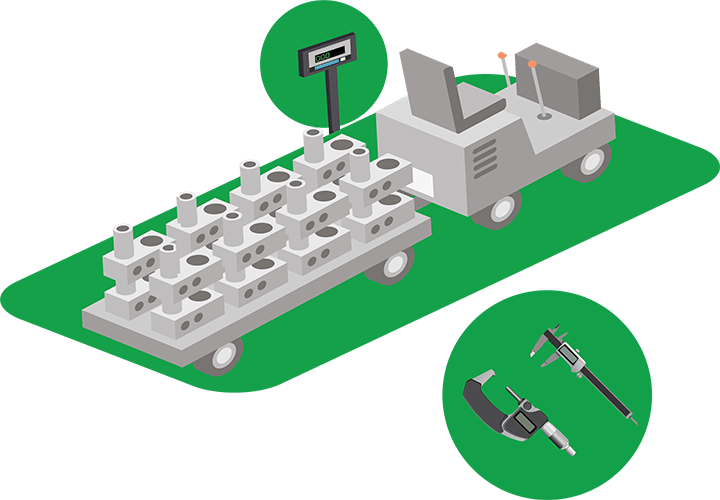

Measurement equipment used in manufacturing is highlighted in green in the photo above.

Quality Control Depends on Quality Manufacturing Measurement Equipment

From counting parts to weighing final products to ensure quality control, you can’t afford to use low quality measurement equipment in manufacturing.

Michelli carries a wide range of high quality weighing & measurement equipment, ranging from high precision measurement tools like vernier calipers & micrometers, to heavy capacity scales.

From counting scales for inventory control to truck scales for final product quality control, we’ve got you covered.

Precision instruments & measurement equipment used in manufacturing is highlighted in green in the photo above.

Let's work together

Contact us today to learn how weighing & measurement equipment can make your day-to-day operations easier.

How is measurement equipment used in manufacturing?

Streamline quality control & maintain consistency with ease

Quality control is simple with the right equipment. Adding quality weighing & measurement equipment that was designed for use in the manufacturing industry can help streamline operations. Incorporating conveyor scales, checkweigher scales & counting scales into the production process can help you ensure uniformity.

Track each piece, part & final product with inventory control equipment

Make inventory management hassle-free by incorporating weighing & measurement equipment designed for inventory control. Counting scales & set point systems can help make tracking more manageable by minimizing error & increasing speed simultaneously.

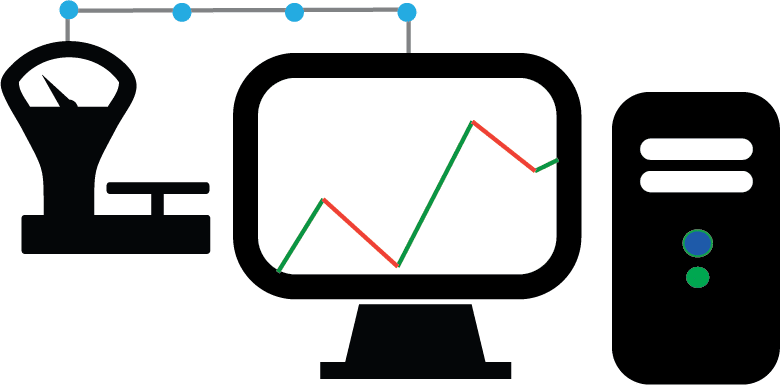

Increase Efficiency With a Weighing System

Michelli develops custom software to run weighing systems that can help customers expedite production, automate processes, generate productivity report, and much more.

Weighing systems create a program that uses your scale as the main input. Imagine freeing up skilled laborers by automating menial processes, or enabling your workers to maintain quality control using only the weight of a finished product. Custom programming can increase safety, productivity & efficiency.

How can accurate manufacturing measurement equipment help in day-to-day operations?

Save Money

Decrease waste by measuring at each stage of production

Decrease loss

Track inventory quickly & easily with counting scales & inventory control equipment

Improve Workflow

Increase productivity without disrupting operations

Increase Efficiency

Utilize set points to streamline bulk packaging

Ensure Quality Control

Minimize product variation with multi-point measurement

Minimize Safety Risks

Ensure products meet exact specification

Services

Available on all makes & models

- Calibration

- Installation

- Data Integration

- Maintenance

- Repair

Manufacturing Measurement Equipment

Light, Medium & Heavy Capacity available

- Dynamometers

- Floor Scales

- Lab Balances

- Micrometers

- Forklift Scales

- Vernier Calipers

- In-Motion Checkweighers

- Torque & Bolting Tools

- Counting Scales

Weighing Systems

Added functionality & productivity

- Data Tracking

- Bulk Packaging

- Set Point Systems

- Belt Scale Systems

Michelli Offers Custom Programming for the Manufacturing Industry

Turn your scale into a multi-tasker and increase productivity.

Some examples of programs we have created for the manufacturing industry include:

- Conveyor weighing programs assist in sorting operations

- Quality control systems ensure uniformity before transport

- In-motion weighing ensures ideal weight during operations

Let’s discuss your application & ways weighing & measurement could help to simplify your process.

Questions?

Contact us. We’re here to help.

View Our Certification Documentation

ISO 9001 Registered Company | ISO 17025 Accredited Laboratory