Michelli Weighing & Measurement Blog

Setting the Standard in Quality Service Since 1947The Michelli Weighing & Measurement blog is full of helpful information from our experts & the manufacturers we represent.

BLH Nobel | The Load Cell – The Work Horse of Weighing Technology

BLH Nobel is a world leader in load cell production, industrial weighing & force measurement. Learn more about the BLH Nobel KIS load cell, designed specifically to produce accurate measurements in less-than-ideal environments affected by wind, heat expansion & more in this video.

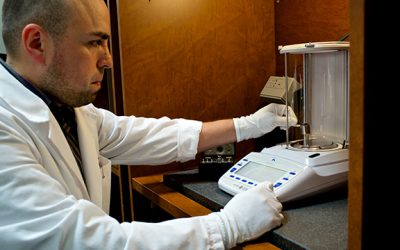

A Tour of the Michelli Weighing & Measurement Calibration Lab

Take a peak inside a Michelli Weighing & Measurement ISO 17025 accredited calibration laboratory in Harahan, Louisiana. Get a brief overview of each work station & learn a bit more about the measurement disciplines we serve.

Mark-10 | Using Force Measurement to Ensure Swim Goggle Quality & Durability

Mark-10 explains how their force measurement equipment was used by a swim goggle manufacturer to perform product quality control testing. With their equipment, software & a custom fixture, product testing was performed to determine the strength of goggle components and the durability of the finished product.

Torque Wrench Care Tips

Review torque wrench 101 & learn some tips from the expert Michelli calibration technicians on proper torque wrench care. Michelli Weighing & Measurement provides manual & pneumatic torque wrench rental & ISO 17025 accredited torque wrench calibration.

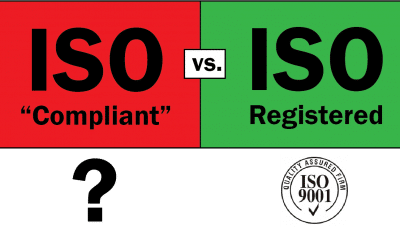

ISO 9001 Registered vs ISO Compliant

When you select an ISO 9001 Registered Organization as your service provider, you have the benefit of knowing they have proven their conformance to the ISO 9001 Quality Management System standard by a showing of objective evidence, and not simply proclaiming self-compliance.

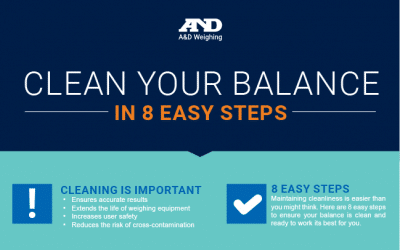

A&D Weighing | How Weighing Equipment Maintenance Ensures Precise Measurements

A&D Weighing explains how to clean your lab balance in 8 easy steps, how to conduct regular checkups to ensure accuracy, the basics of when to calibrate & tips on how to keep your maintenance schedule under control. To keep equipment performing precisely over the long-term, use these best practices to maintain exacting performance.

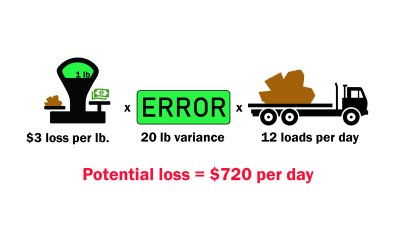

How much could an inaccurate truck scale cost you?

Inaccurate scales & measurement equipment could cost you thousands It’s no secret that preventative maintenance is the key to getting the longest life out of your weighing & measurement equipment. Regular inspections by a certified...

B-TEK Scales | 4 Ways a Dirty Truck Scale Can Cost You Money

B-TEK Scales explains situations in which dirty truck scales can cost money, and what actions you can take to prevent it from happening to you. Keeping up with your scale maintenance is the easiest way to remain in compliance, save on maintenance costs and prevent downtime.

How Regular Scale Inspections Help You Save Money

Regular scale inspections allow users to remain in compliance & prevent measurement equipment malfunctions that could directly affect quality, cost & safety. Every organization should have a preventative maintenance plan in place, & an inspection schedule is the primary portion of that plan. There are 3 key factors to consider when developing an inspection schedule…

Avery Weigh-Tronix | How to Properly Clean Washdown Scales & Checkweighers

Richard Lund at Avery Weigh-Tronix describes how to properly clean washdown safe scales & washdown safe checkweighers. Keeping your weighing equipment clean prevents contamination, aids in compliance with regulations and keeps your scale running at peak performance.

Intelligent Weighing Technology | Preventative Maintenance & its Part in a Production Environment

Richard Sharpe from Intelligent Weighing Technology explains why it is good practice to regularly test and calibrate your equipment. Weighing equipment is dynamic in the way that it is always moving when in use. Things that move experience wear, they get abused and moved and therefore it is good practice to regularly test and calibrate your equipment.

How to Clean Your Scale & Measurement Equipment Properly (and Why It’s Important)

Keeping your measurement equipment clean allows it to function properly by keeping compartments, junctions & electrical components clear of obstruction. Here are tips on which cleaning method to use, and a few things to take into consideration when determining how often you should clean your equipment.