Types of Calipers & How to Choose

There are a few basic types of calipers. Every type can provide dimensional measurements of the distance between 2 points, including the thickness & diameter of an object. Some calipers can also measure depth. So if all calipers can basically provide the same measurements, why are there different types and how do you decide which to use?

Each type of caliper utilizes a different output method for communicating the measurement reading to the user. The type you should choose depends on the application in which the tool is being used & user preference. Let’s examine the three basic types of measurement calipers to develop a better understanding.

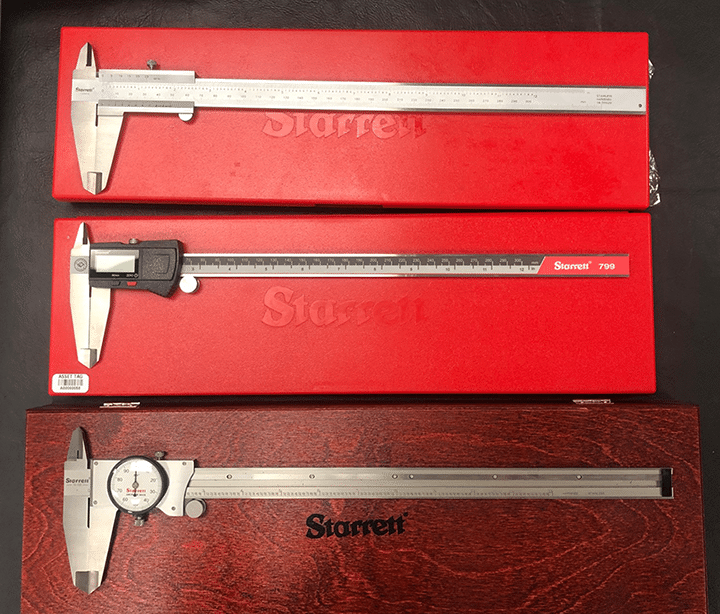

Basic Caliper Types Used in Precision Measurement

- Vernier caliper

- Digital caliper

- Dial caliper

Vernier calipers – The most reliable option

Tip from our calibration lab manager:

“The other types [of calipers] introduce additional features that can fail, where this one has more of a minimalist design that doesn’t sacrifice quality”

Vernier caliper measurement reading

Vernier calipers generally have a resolution of 0.001” if using imperial units, or a variant of 0.02 mm or 0.05 mm if using metric units, meaning they can provide precise measurements up to 1/1000th of an inch. There is an opportunity for user error with this type of device, as it uses 2 scales to provide a measurement reading: the main scale & the vernier scale. The main scale provides the main number and the first decimal place of the measurement reading, while the vernier scale provides the second decimal place.

Advantages of the vernier caliper

This caliper is the most economical option, although there are a few options that can get quite expensive. Also, while some vernier calipers only display units in either metric or imperial, options that display both units are available.

The vernier caliper is the most reliable option available because it can be used in wet, dry, oily or magnetic environments. Also, because it does not require a power source, this caliper offers more flexibility and can be used in a wide range of applications. Many users prefer the mechanical calipers over digital options.

The key disadvantage of the vernier caliper is that it is less precise than a dial or digital caliper.

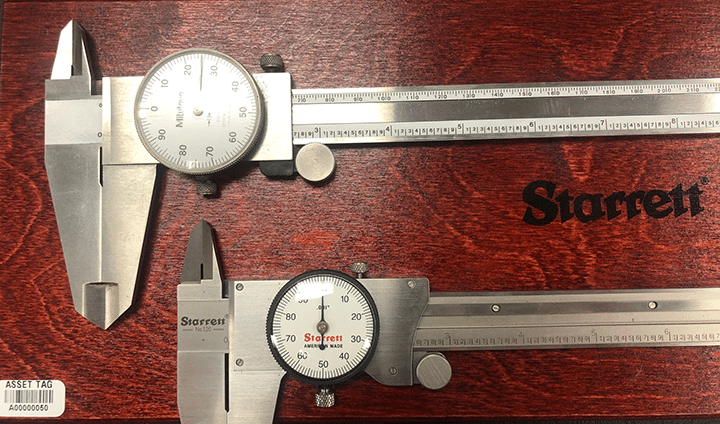

Dial calipers – The most precise option

Dial caliper measurement reading

Dial calipers provide precise measurements up to 3 decimal places, or 1/1000th of an inch. Obtaining a measurement is a 2 part process on this device as well, as it uses both a main scale and a dial scale. The main scale graduations on a dial caliper represent .1 inch intervals, while the graduations on the dial represent .001 inch intervals. Users combine the 2 readings to reach the final measurement reading.

Advantages of the dial caliper

The dial caliper is mechanical, so it requires no power source to provide a reading. However, the rack & pinion system used in this device is fragile, and the tool is rendered useless if the dial is broken. This caliper is available in options that display units in only metric, only imperial, or both metric & imperial.

The key disadvantage of this device is that it is sensitive to magnetic fields, which means it is not effective in as many applications as the vernier caliper.

Digital calipers – The simplest & fastest option

Digital caliper measurement reading

Digital calipers provide precise measurement readings up to 3 decimal places as well, or 1/1000th of an inch. This version is the simplest to use, as it produces measurement readings instantaneously.

Advantages of the digital caliper

First and foremost, digital calipers allow users to set a reference point & more quickly find differences from that point. (A dial caliper has this ability to some degree as well.) Typically, digital calipers also have a button that allows users to switch between metric & imperial readings instantly. These features, coupled with the instantaneous reading it produces, means this caliper is the fastest option to use. Also, some digital calipers have the ability to transmit data, saving users time by omitting the process of recording data by hand during use.

The key disadvantage of the digital caliper is that it requires a power source. Because of that, the tool is susceptible to damage from moisture or battery corrosion. The digital caliper could also be affected by magnetic fields. Lastly, this is the most expensive option.

How to Choose the Right Caliper

When choosing a caliper, the decision comes down to a combination of user preference & the type of application in which the tool will be used. Each option will provide accurate & precise measurements as long as the tool is properly maintained. As mentioned, the digital caliper is the most sensitive to moisture, and the dial caliper is the most sensitive to drops. However, all precision measurement equipment should be handled with care. Here are some maintenance tips that are applicable to all types of calipers.

For more information on proper dimensional tool maintenance, read our post Dimensional Tool Care Tips.

Caliper Maintenance Tips:

- Always store calipers in the case provided with the tool to protect against damage

- Pack with desiccant packs to protect against moisture damage

- Treat the device with silicon-free lubricant to protect against rust

Maintenance tip from the Michelli Weighing & Measurement calibration lab manager:

Drops are one of the most common ways that any caliper is damaged beyond repair. Many times when the caliper is dropped, it falls on one of the outside or inside measurement jaws, which creates a burr on the measuring surface.

You can check if the jaws have damaged tips by holding the closed calipers up to a light, then looking for any points that allow visible light through. All calipers are equally susceptible to this damage, regardless of readout. Higher end manufacturers use better materials that are more resistant to this type of wear/abuse.

The Michelli Weighing & Measurement team makes it easy to properly care for your precision measurement equipment.

We offer repair and both standard NIST Traceable & ISO 17025 accredited calibration service on a wide range of measurement equipment. Ship your precision measurement equipment to our calibration labs, where Michelli experts provide service & maintenance tips to ensure you get the longest useful life out of your equipment.

We can also help you remain in tolerance with TRAC, the asset management system available to all Michelli Weighing & Measurement customers. TRAC helps you track records, assets & calibrations. Users can also set maintenance plans for each asset, which enables automatic reminders as calibration due dates approach. Learn more about TRAC here.

Need to purchase a caliper or have yours serviced?

Contact Michelli Weighing & Measurement today to request a quote. Our experts will help you determine the right equipment for your application, and help you keep your equipment in tolerance.