Proper Dimensional Tool Care

Proper dimensional tool care can lengthen the usable life of your tools and help to ensure accurate measurements. Regular physical/dimensional tool calibration, performed at an accredited calibration lab, can help ensure your tools are providing accurate readings, but what are some best-practices you can implement to maintain your tools on your own?

The largest threat to the integrity of dimensional tools is environmental degradation. Environmental factors like moisture & dust can severely impact the usability of your equipment. Here are some dimensional tool care tips you can use to protect your tools to ensure you get the most out of your equipment.

Preventing Rust on Your Dimensional Tools

Often, people believe that temperature control is the main concern when caring for dimensional tools, but that isn’t the case. Temperature variations don’t affect the tools, but moisture can cause huge problems.

According to the Michelli Weighing & Measurement experts, rust & corrosion are the most common threats to dimensional tool integrity. Moisture causes metal to rust, and rusty dimensional tools produce inaccurate measurements & are difficult to use. Here are a few tips you can use to prevent rust on your dimensional tools.

1. Store dimensional tools in wooden cases

Many manufacturers package dimensional tools in plastic cases. Plastic is far less capable of absorbing moisture than wood. Any moisture trapped inside of a plastic storage case will remain there. If a dimensional tool is stored inside of a plastic case, that trapped moisture will eventually react with the metal in the tool, producing rust & causing corrosion.

Wood will come into equilibrium with the relative humidity of its environment. A wooden case will swell or shrink to adapt to its environment, but the contents of the case will not be affected. Therefore, wooden cases better protect dimensional tools from moisture in the air than plastic cases.

2. Use moisture absorbing desiccant packs when storing dimensional tools

Desiccant packs absorb moisture. You may have seen small desiccant packs in shoes, clothing, or other products. Those type of packs might read “Silica Gel, do not eat”. There are many types of desiccants made from a wide range of materials, including clay, activated carbon, silica gel, and more, designed to absorb moisture in specific environments.

Storing your dimensional tools with desiccant packs can help reduce moisture, to aid in preventing rust. If plastic storage cases are the only available option for your dimensional tool storage, desiccant packs are a MUST for minimizing rust damage. You can purchase desiccant packs from a wide range of sources. Prior to purchasing, do your research to determine which desiccant will be the most effective in your environment. Environmental factors determine the best desiccant to use for your dimensional tool storage, including temperature, relative humidity & the duration of time the tools will be exposed to these factors.

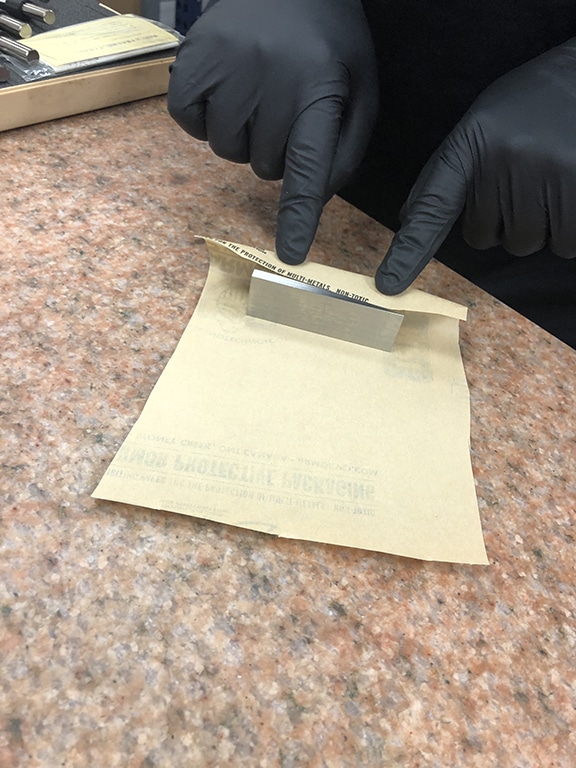

3. Use corrosion inhibiting (VCI) paper in dimensional tool storage

VCI paper is Kraft paper that has been combined with vapor corrosion inhibitors. This paper is specifically designed to protect both ferrous & non-ferrous metals by slowly releasing chemical compounds that actively work to prevent surface corrosion. Use VCI paper to wrap tools prior to packaging to protect your dimensional tools from moisture.

Dimensional Tool Cleaning Tips

Dimensional tools are high precision instruments, and proper maintenance includes attention to detail when cleaning & storing these instruments. While dust may seem like a minute detail, it can affect the integrity of your dimensional tools over time. For example, dust can scratch the flat anvil & spindle faces on a micrometer. Each time you use a micrometer, you should check these plates to ensure that no dust has accumulated on the mating plates.

1. Use lint free cloths to clean dimensional tools often

Keep your dimensional tools dust free by cleaning with lint free cloths. Also, because a lint free cloth does not produce fluff, it is less likely to build-up static electricity in the device, which can attract dust. So, using lint-less cloths to clean your tools safely removes dust, and also helps prevent dust from settling on these tools in the future.

2. Use a silicone-free lubricant to maintain your dimensional tools

Industrial lubricants can help clean dimensional tools, and protect against moisture, rust & corrosion. However, not all industrial lubricants are created equally. Silicone-free industrial lubricants are dust resistant to protect your dimensional tools, whereas the film left behind by a silicone-based lubricant attracts dust. As discussed earlier, dust is detrimental to dimensional tools.

Starrett produces an industrial lubricant called M1, which is silicone-free and dries instantly. Starrett’s M1 helps repel dust, moisture and contaminants, to help extend the usable life of your dimensional tools. Michelli Weighing & Measurement is an authorized Starrett distributor, so you can purchase M1 through your local Michelli account manager.

Protect your investment

Precision measurement devices, including dimensional tools, are an investment. These precision instruments require special care & maintenance. Proper dimensional tool care is essential to getting the longest usable life out of your equipment. Using these tips & employing a regular calibration schedule will help to ensure the accuracy of your measurements & get the most out of your investment. Michelli Weighing & Measurement can help with your dimensional tool calibration. We provide both standard NIST traceable calibration & ISO 17025 accredited calibration on a wide range of precision measurement devices. Visit our calibration page to learn more, or contact us to request a quote.

Looking for more tips on how to care for your equipment? Check out our blog post Torque Wrench Care Tips next.

Ready to invest in quality dimensional tools?

Contact Michelli Weighing & Measurement today to request a quote. Our experts can help match you with the right tools for your application & your environment.