Different Types of Checkweighers

Static Checkweighers are often used when hand-processing raw meats, fish, or soft fruits. QA inspectors heavily utilize static checkweighers to ensure that products stay within tolerance along the manufacturing process, ensuring that production lines run smoothly.

In-Motion Checkweighers are used toward the end of lines and usually perform a final weight check after finished goods are packed.

Multi-Head Carousel Checkweighers are used on fully automated packing lines. They quickly build up the target weight using 16 mini-weight head scoops. The scale calculates the weight of each scoop, and internal checks only allow the scale to tip in the number of scoops that add up to the correct final target weight.

Legal-for-Trade and Non-Legal-for-Trade: Many static checkweighers carry a National Type Evaluation Program (NTEP) approval or EU Type Examination Certificate for use in legal-for-trade applications. Even though 80% of static checkweighers do not require legal-for-trade scales, using an approved scale can give users extra insurance that the scale will deliver the accuracy needed to keep their lines running efficiently.

The Benefits of Modern Checkweighers

Speed

Avery Weigh-Tronix checkweighers have a stability of less than half a second. Because the scale calculates weight much faster than any operator can work, the operator is never waiting for the scale to stabilize, ensuring that AWTX products never hinder our customer’s production lines.

Reduced downtime

Checkweighers must be reliable and physically robust. They take a lot of abuse from everyday use and cleaning. Scales with reliability issues soon become costly to repair or replace and can easily slow or stop production. To avoid these problems, Avery Weigh-Tronix designed our scales to resist the regular wear and tear that comes with manufacturing environments and allow for easy part replacement.

Flexibility

Being able to change the target weight parameters quickly is critical for many manufacturing lines. It is standard across food manufacturing for scales to be switched out daily and replaced with cleaned and sanitized units. Avery Weigh-Tronix checkweighers use stored PLU data saved onto the scale to change weight tolerances for the next production run quickly. Some models even allow for remote setup from an internet-connected PC. Our checkweighers can be rapidly set manually by placing a known test weight on the scale and pressing the ‘Target Key’ on the checkweigher.

Data Capture and Retrieval

These checkweighers gather other valuable weight data in the background to allow the line to run as efficiently as possible. This data captured can be as simple as recording every stable weight for standard deviation analysis or as complicated as capturing statistical data like X bar R for tracking trends within the process line. As mentioned above, data captured by a checkweigher can also be used to quickly identify vital machine adjustments that need to be done throughout a shift or to identify a potential machine failure long before the actual failure occurs.

Most modern checkweighers can transmit and receive data directly from the scale. Several communication port methods are usually available, from RS-232, USB, and Ethernet to Wi-Fi. Although invaluable for many process lines, running data lines within a food-safe washdown area is not always possible and can be costly to install. However, scales like our ZQ375 Checkweigher can collect and store data internally without connecting communication ports. This data can be retrieved manually by plugging in a portable USB memory drive into the ZQ375 or automatically transmitted wirelessly to a computer.

More Things to Consider

Scale Hygiene and Cleaning: Because checkweighers are used heavily in food processing, they must be easy to clean and designed with as few bug/bacteria traps as possible. This is why many customers prefer food-grade pickled and electropolished stainless steel over other lower-cost scales. All weld areas must be continuous welds because even professional seam welds can harbor unwanted bacteria. When buying a checkweigher look for a food safety certificate (like NSF/ ANSI Standard 3-A 14159-1 -2010). These classifications tell customers that the product was designed with hygiene and cleaning in mind and can be used in a food environment.

Knife Resistant Overlays: Overlay key damage is often due to constant knife presses on set keys. Although pressing buttons with a knife tip is not recommended, it can often happen on any busy meat-cutting floor where users often wear bulky gloves for safety. Avery Weigh-Tronix designed a special knife and chemical resistant protective layer on the keypad overlay to minimize any keypad damage. Additionally, internal connections are provided for external industrial switches to also remove the need to touch the keypad overlay with a knife.

Critical Information on Failure Risks

Regarding failure risks, there are two common faults: load cell damage or water ingress.

Load cell damage usually occurs when scales were not designed for how they were being used. They may not have the correct overload or shock load protection required for the everyday wear and tear on manufacturing floors. Our ZQ375 Checkweighers use our torsion base design, which has 500% overload and shock load protection significantly cutting back on the risk of load cell damage.

Water ingress failures can occur due to three main failure areas: improperly fitted cable glands, imperfections in case enclosure design, or damage to the overlay. Additionally, food-grade checkweighers must remain watertight even with massive shifts in temperature and pressure. Scales that do not have a way to neutralize this temperature/pressure shift within the scale can quickly suffer damage from a capillary action that sucks in moisture through seals, gaskets, or cuts in the overlay. Avery Weigh-Tronix’s ZQ375 Checkweigher uses “gore vents” to prevent such events. These vents are designed to keep the water molecules out while allowing the enclosure to breathe and neutralize all capillary action. A simple solution to a common problem most other checkweighers might encounter in real world applications.

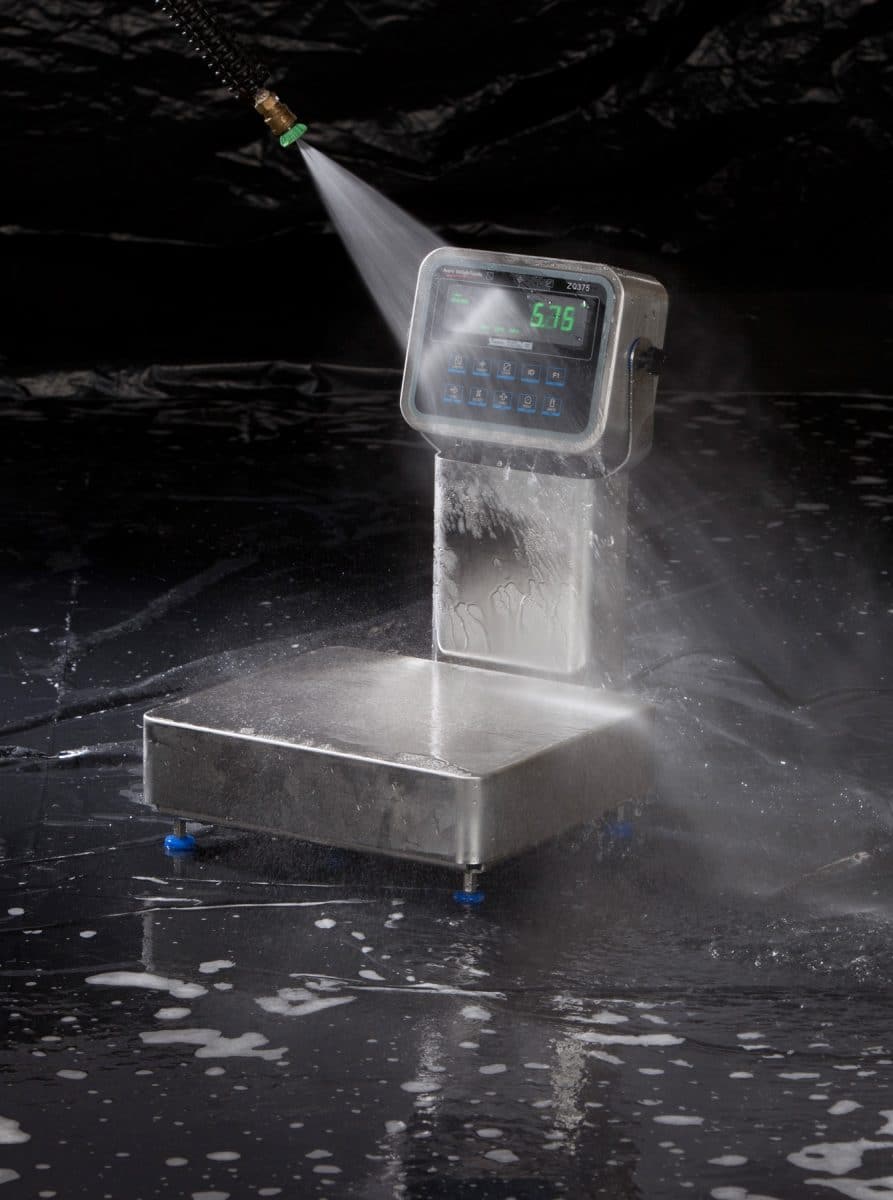

Water ingress protection: Protection against water damaging the electronics of a checkweigher is crucial to long productive operation. An independent lab conducted extensive testing on the enclosure of the ZQ375 Checkweigher and has certified an IP69K rating for water ingress making this model ideal for industries where high pressure washdown sanitation is a primary concern. Testing for this rating places the specimen on a turntable spinning at 5 revolutions per minute while being constantly sprayed with 1450 PSI water heated to approximately 176°F repeatedly, every 30 seconds, at 0°, 30°,60°,90° angles. Having this certification means your checkweigher can be used with confidence in harsh environments with high pressure cleaning applications.

Use What You Know!

Using the above information, ask yourself the following questions when evaluating your current checkweighers or are considering adding checkweighers to your manufacturing lines.

For existing checkweighers:

-

- Are you getting the most out of your current checkweighers?

- Could you change the location of your checkweighers to expand their functionality?

- Are your scales used for packing only? If so, could you also leverage the data capture functionality to help your organization improve its processes and products?

- Are you currently using a static/in-motion checkweigher on an automated line that may be better suited for the accuracy of a multi-head carousel checkweigher?

For new checkweighers:

-

- What environment will your checkweighers occupy?

- What is the cleaning/hygiene requirements for that environment?

- Will the checkweighers need to be legal-for-trade?

- Is capturing a product’s weight data important today or possibly in the future?

- Is it possible to use communication cables for the impacted lines?

- Is Wi-Fi enabled reporting something your organization would be interested in?

To wrap up, Avery Weigh-Tronix specializes in providing customers with well-designed and long-lasting checkweighers that offer fast, accurate, and robust solutions to almost any customer need. Our checkweighers are designed from the start to be in line with all major industrial governing bodies, making them ideal for use on any cutting floor, packing line, or other manufacturing facilities. Beyond normal weighing functions, our checkweighers offer quality inspectors and leadership vital data to keep fast-moving lines compliant and working efficiently.

Avery Weigh-Tronix is one of the world’s leading suppliers of weighing scales, systems and equipment.

We offer a wide range of industrial weighing systems and solutions, backed by an extensive service network throughout the USA.

Part of a large corporate family, we market and service our products in over 80 countries across the globe.

Our Experts Can Help You Find the Right Checkweigher

Contact your local Michelli Weighing & Measurement team of experts today. We can help you find the right checkweigher for your application.