Caliper Basics: What is a Caliper?

Caliper basics begin with explaining what a caliper is and how it differs from other types of precision measurement instruments. The caliper is one of the most versatile types of precision measurement equipment. It may even be considered the Swiss-army knife of precision measurement devices. While most other precision instruments are highly specialized and designed to provide one specific type of measurement reading, the caliper can provide measurements of multiple physical dimensions, including inside dimensions, outside dimensions, and even depth readings.

For example, imagine a bolt is missing on a piece of construction equipment. A caliper can be used measure the depth and outside diameter of the hole. The user could also use a caliper to measure and compare the thickness of a range of bolts to choose the best option to use in the hole to replace the missing one.

While calipers may be more flexible than other types of precision measurement devices, they are not necessarily more accurate. Sure, a caliper provides a more accurate measurement reading than a ruler. (Calipers provide measurement readings with an accuracy of up to 0.001 inch.) However, a micrometer, for instance, is more accurate than a caliper. So another precision measurement instrument may be a better fit for applications requiring higher accuracy.

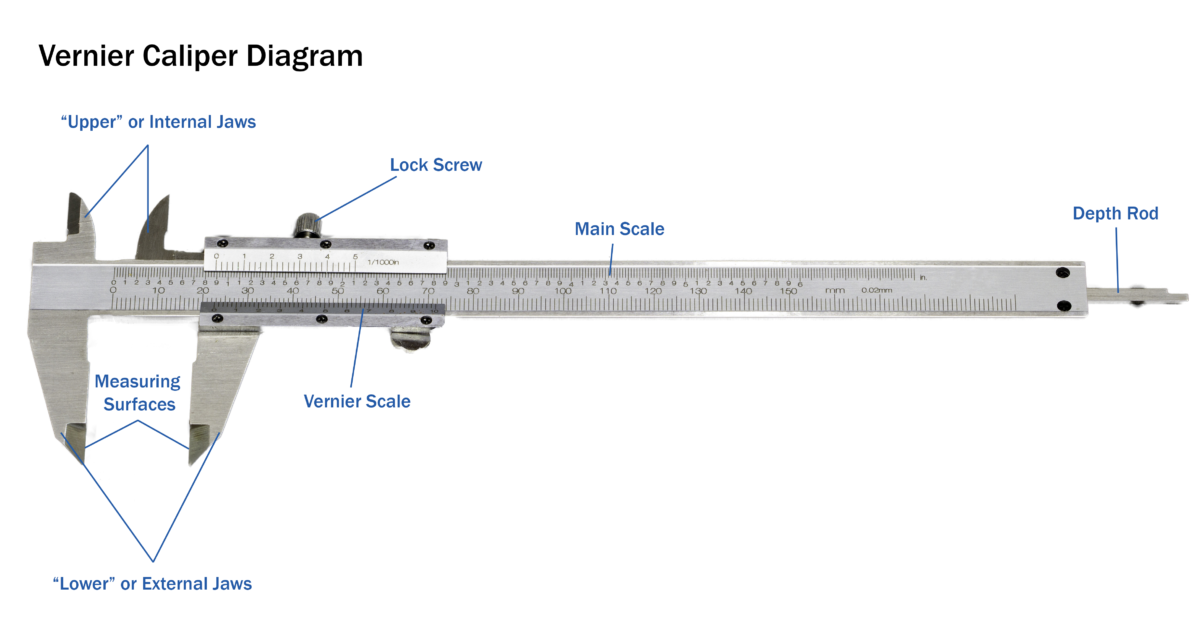

Parts of the Instrument

A caliper has 2 sets of or “jaws”. These include the smaller, upper (a.k.a. “internal”) jaws, and the larger, lower (a.k.a. “external”) jaws. Each set of jaws is used for a different purpose. For example, the lower jaws of a caliper might be used to measure the thickness, or the outer diameter of a bolt. Whereas the caliper’s upper jaws would be used to measure the inner diameter of the same bolt.

The sliding jaw and lock screw allow the user to adjust the caliper, lock the jaws in place to ensure accuracy, then take the reading. The main scale provides the initial measurement. Then, depending on the type of caliper, a vernier scale or a dial indicator could provide a subdivision of the main scale, which enables the user to take the most accurate measurement. Lastly, the depth rod enables the user to take depth measurements of holes.

Caliper Basics: The Three Main Types

There are 3 main types of calipers, and a few specialty types. The three basic types of calipers are the vernier caliper, the dial caliper & the digital caliper. We will review the basic differences below. To learn more about each, please visit our blog How to Choose the Right Caliper.

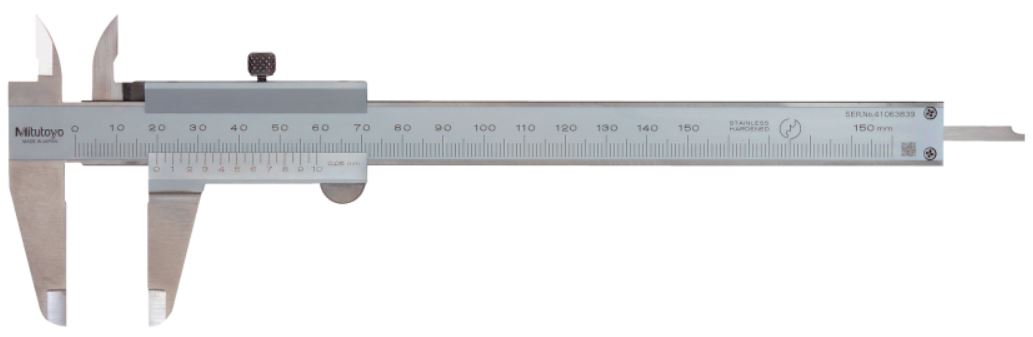

Vernier Caliper (pronounced like ver-neer)

The vernier caliper is both the most economical type of caliper, and the most reliable option. This is because it does not require batteries, and it can be used in wet, dry, oily or magnetic environments. The vernier caliper utilizes a vernier scale and a main scale to provide readings. The vernier scale is attached to the mobile external (lower) jaw and provides a further subdivision of the main scale’s division. To obtain a reading, the user adds the value displayed on the main scale to the value displayed on the vernier scale to get the most accurate measurement.

Imagine an oilfield worker needs to replace a bolt on a pump in the field, but he isn’t sure what size the bolt is. He could utilize a Vernier caliper to determine the correct replacement bolt size without ever leaving the site.

Dial Caliper

The dial caliper is the most precise type of caliper. The dial caliper requires the user to combine the larger measurement (to the left of the jaws) and the reading showin on the dial indicator. The dial caliper is also sensitive to magnetic fields.

Whole inches, tenths of an inch, hundredths and thousandths of an inch on the dial face.

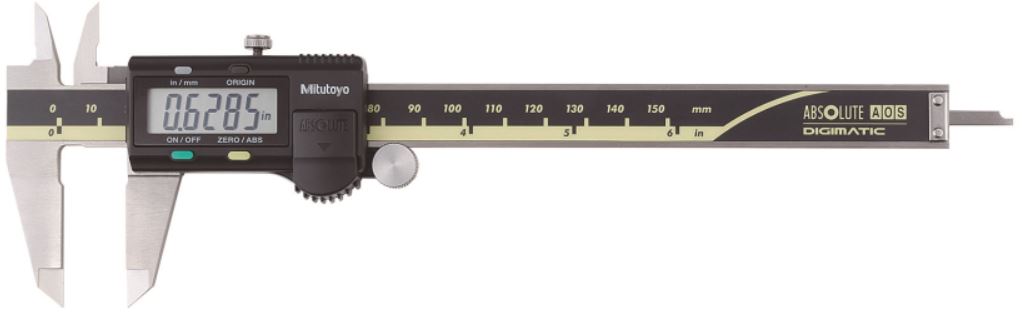

Digital Caliper

The digital caliper is the easiest type of caliper to use. The operator can obtain measurements instantaneously, without performing any addition. Plus, the digital caliper can perform conversions with the touch of a button. Because of this, some operators may consider the measurements produced by a digital caliper more reliable. However, this simplified user experience translates into a higher cost. The digital caliper is the most expensive option & it requires batteries to function.

Caliper Basics: Maintenance

Calipers are precision measurement instruments, and should be treated as such. A caliper should be cleaned after every use with a lint free cloth, and any dirt, oil or other debris should be thoroughly removed. The measuring surfaces of a caliper should also be wiped clean with a lint-free cloth prior to each use to ensure the integrity of the measurement readings.

To prevent dropping or other damage, users should store caliper in the original manufacturer’s case when they are not in use. It is important to note that calipers are highly susceptible to temperature fluctuations, so user should store them with dessicant packs in areas with minimal temperature variations & low humidity. For more information on proper precision measurement instrument maintenance, view our post Dimensional Tool Care Tips.

Ready to Purchase a New Caliper?

Let the experts at Michelli Weighing & Measurement help you choose the best option for your application. Contact your nearest location today.