Belt Scales Help Facilitate Accurate Material Measurements in Rugged Environments

Belt scales are rugged devices that can be added to conveyor belts to provide real-time, continuous weighing of materials moving down the conveyor—helping users streamline operations, keep inventory in check, and maximize efficiency. Precision matters, especially in applications where pricing is based on weight.

Belt scales are an imperative tool to ensure accurate material flow measurements in industries like mining, aggregates, agriculture, or food processing. Whether the environment is rugged, like in a quarry, or more controlled, such as a food processing plant, the addition of a belt scale is a great way to increase efficiency.

How do Belt Scales Work?

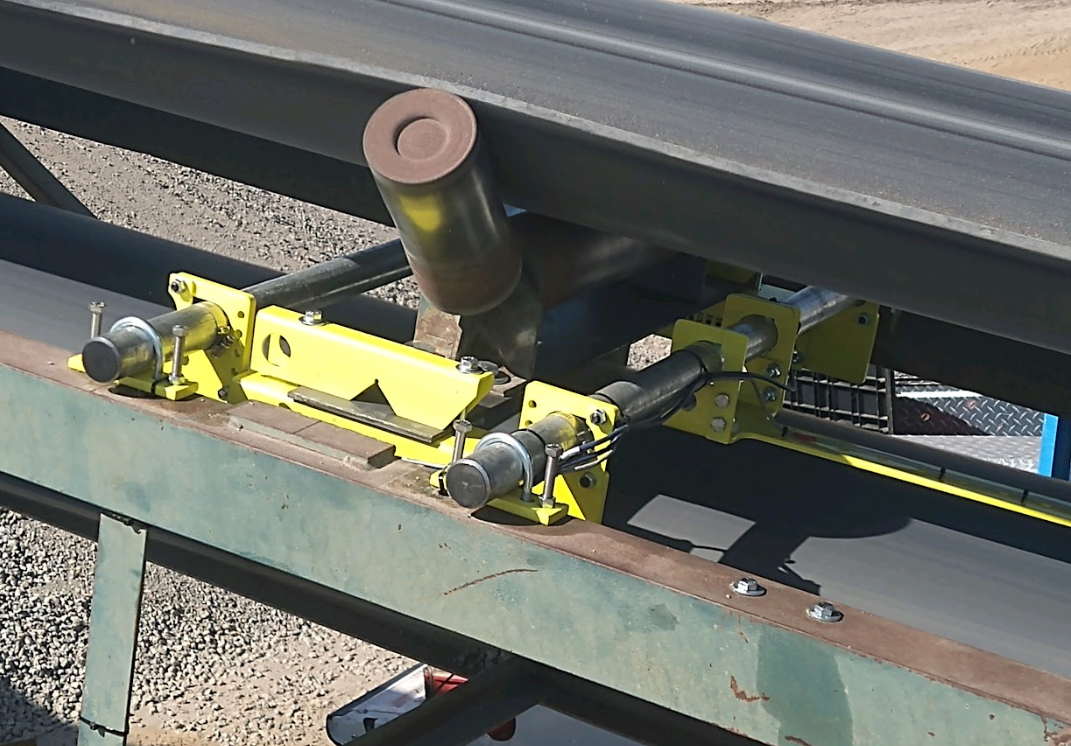

Belt scales, also called conveyor scales, are built right into conveyor belts, enabling users to capture the weight of materials as they move along the conveyor.

As material flows down the conveyor belt, across the belt scale, it actually utilizes load cells to gather weight information, then processes that, along with flow rate information from speed sensors to calculate weight readings—all without slowing down production. So belt scales enable users to capture weight data without interrupting other operations. By incorporating weighing into an existing process, operators are able to maximize productivity.

Why Use Belt Scales?

1. Gather Real-Time Data Without Interruptions

With belt scales, there is no need to stop production to facilitate weighing. Belt scales can provide live updates, giving users the power to make operational decisions as needed.

2. Boost Efficiency

Belt scales allow users to monitor material flow rates, adjust operations instantly, cut down on waste, and maintain consistent output.

3. Stay on Top of Inventory

Accurate weight readings equate into better inventory tracking—helping users avoid overstocking product or running short on materials.

4. Ensure Quality Control

Whether processing food or handling bulk materials, facilitating the consistent flow of materials is crucial. Belt scales help keep things running smoothly by adding a quality control function to an existing operation.

5. Meet Industry Regulations

Need to provide accurate reports for compliance? Belt scales provide the precise data required to meet industry regulations.

Finding the Right Belt Scale

Not all belt scales are the same. Determining the best scale for an application depends on factors like required flow rate, the material type passing over the conveyor, and environmental conditions.

That’s where Michelli Weighing & Measurement comes in—we’ll help you find the best belt scale for your business.

Why Work with Michelli Weighing & Measurement?

At Michelli, we get it—accuracy and precision are crucial, but not at the cost of efficiency or productivity. Our experts will guide you through the process of selecting the right belt scale for your application. Then, we can install it, calibrate it, and help you maintain it. Our goal is to help you find the equipment you need and keep it running at peak performance. With years of experience in weighing technology, we’re here to provide the solutions and support you need.

Want to improve efficiency and get better control over your material handling?

Contact your local Michelli Weighing & Measurement office today. Our experts will help you find the right belt scale for your application.