Intrinsically safe balances and scales for safer weighing in hazardous areas

Solutions for environments with potentially explosive atmospheres

What is a Hazardous Area?

A hazardous area is where there is sufficient amount of explosive gas, dust or vapor to potentially cause a fire or explosion. This includes normal and abnormal conditions, such as a spill. For an explosion to occur, there must be:

• Fuel: usually the liquid or gas being transferred or weighed

• Oxidizer: typically oxygen in sufficient quantity to combust

• Ignition Source: a spark or high enough heat exceeding the flame point of a vapor

Suppressing any of these 3 is usually enough to avoid ignition.

Intrinsically Safe vs. Explosion Proof

These terms may sound similar but are really very different. Intrinsically safe scales are designed to limit heat generation and ignition due to elevated voltage or current. By contrast explosion-proof devices don’t have to be inherently incapable of ignition, they are enclosed in a housing that can contain an explosion. If the device does explode, flames and gases cannot escape the housing and spread through the facility. However, the penalty is a heavier, bulkier enclosure, making them suitable only for fixed installations.

Types of Classifications

Areas with possible fire or explosion risks due to explosive atmospheres and/or mixtures – are called hazardous (or classified) areas or locations. In North America, these areas are historically classified with the Class/Division system. In Europe and the rest of the world – but also more and more in North America – the Zone system is used.

The National Electrical Code (NEC) assigns classifications based on inherent flammability and location. Areas are rated based on how persistent are vapors. For example, inside a petrol tank vapors are always present, so is classed as Division 1. The area outside the tank may have vapors, or only intermittently, and is classed Division 2. See table below.

Choosing the Right Equipment

Only you can assess your environment and determine if it matches the capabilities of the EK-AEP or HW-CEP Series. Study the certifications and decide if it is suitable for your application.

| Substance | Substance Class | Area Classification | Hazardous Location Characteristics | |

| NEC500 | NEC505 | |||

| Gases/Vapors |

Class I (NEC 501) |

Division 1 |

Zone 0 Zone 1 |

Explosion hazard present continuously or occasionally under normal operating conditions |

| Division 2 | Zone 2 | Ignitable concentrations of flammable gases or vapors are not normally present, but could be present in the case of a fault | ||

| Dusts |

Class II (NEC 502) |

Division 1 | Combustible dusts are presents in quantities sufficient to produce explosive and ignitable mixtures | |

| Division 2 | Combustible dust due to abnormal operations may be present in quantities sufficient to produce explosive or ignitable mixtures | |||

| Fibers |

Class III (NEC 503) |

Division 1 | Easy ignitable fibers / flyings are handled or manufactured | |

| Division 2 | Easy ignitable fibers / flyings are stored or handled | |||

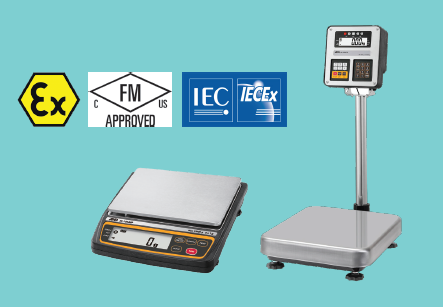

A&D offers solutions for hazardous area weighing environments:

EK-AEP for lower capacity/higher resolution applications as typically found in a fume hood and when you need to collect data.

HW-CEP for heavier capacity and general industrial applications.

Start Weighing Safely the Same Day You Receive Your Balance or Scale

A&D intrinsically safe models use alkaline batteries, so you save the expense of intrinsically safe barrier wiring which must be installed by a qualified electrician.

Both models are Factory Mutual (FM) approved for Class I, Div I, Groups C&D and Temperature T4 in both the United States and Canada. The Class I rating and high resolution offered by the EK-AEP make it ideal for expensive gas filling applications and

the heavy capacity of the HW-CEP allows for taring of heavy gas cylinders which are commonly used.

3 EK-AEP models with capacities from 300 g to 12 kg, all with oz and lb units (except 300g). The HW-CEP weighs in oz, lb, g, kg.

Click here to download the A&D Intrinsically safe balances and scales for safer weighing in hazardous areas Product Note PN-14 in PDF format

The following post was provided by A&D, our featured manufacturer this month. A&D is a world leader in the design and manufacturing of precision measurement and product inspection equipment for the health care, laboratory, and other industrial markets. The A&D Medical, A&D Weighing, and A&D Inspection business units are all renowned for developing reliable, market-proven solutions for the customers they serve.

We Can Help You Get the A&D Equipment You Need

Contact your local Michelli Weighing & Measurement team of experts today. We can help you decide on the right intrinsically safe balances and scales for safer weighing in your hazardous environment.